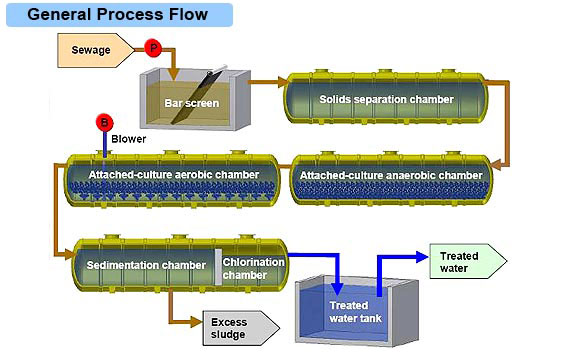

Conventional Sewage Treatment Plant uses activated sludge process to biodegrade and remove pollutants from wastewater for discharge or reuse purposes.

Conventional sewage treatment systems are based on activated sludge process and its variations. These included

Conventional sewage treatment system can be prefabricated with durable FRP tanks and minimum site installation works are involved.

Conventional sewage treatment plant occupies larger space than MBR plant as separate activated sludge reactor and secondary sedimentation tank are required. Site works and civil works are minimised as the plant is prefabricated in FRP Tanks. In order to meet more stringent reuse requirement, which is beyond what can be accomplished by conventional sewage treatment plant; a tertiary treatment (filtration) is incorporated when requested, to further polish the secondary treated water.

Treatment Chambers

Hitachi Aqua-Tech also designs and installs Sequencing Batch Reactor (SBR) and Moving Bed Bioreactor (MBBR) sewage treatment plants (STP) for our clients.

Sequencing Batch Reactor is a batch process reactor where different reaction phases takes places in sequence: fill, react, settling, idle; When one cycle of the treatment is completed, the next batch of the wastewater is filled into the tank again and the process continues.

SBR process is suitable for small to medium sized sewage treatment plant.

Some features of the SBR systems are:

Moving Bed Reactor process utilises attached growth biological process for BOD removal. Due to the high density population of the different types of bacteria growing in the carriers, MBBR process improves reliability, simplify operation, and require less space than traditional wastewater treatment systems.