In an oil production environment, seawater is injected into a reservoir to maintain pressure and ensure that hydrocarbons are channeled to the producing well. The quality of water for injection has to meet a certain water quality to prevent plugging / scaling of the injection equipment. This is of utmost importance as drilling a new well or purchasing a new set of drilling equipment is extremely expensive in an offshore environment.

Traditionally, seawater contains significant amounts of barium and strontium ions. These ions have strong affinities with sulfate to form strontium sulfate or barium sulfate which will in turn become precipitates that will be deposited on the pipe internals and machinery components. These scales are hard to remove as they are not soluble. Hence, the most convenient way of preventing this occurrence will be to remove sulfate ions from the feed water.

Sulfate Removal Unit or Package consists of:

Sulfate removal is a technology utilised by the oil industry to produce low sulfate water for injection. This technology is based on using nanofiltration (NF) membranes to remove the divalent sulfate ions. Traditional seawater reverse osmosis (SWRO) system is not used for this process as SWRO utilises a larger energy consumption to drive water through the membrane due to its denser membrane structure. Separation by NF occurs predominantly due to size exclusion and electrostatic interactions hence, requires lower energy to drive water across the membranes.

| Applications | Industry |

|---|---|

| Injection Water for Oil Production | Floating Platforms Storage and Offloading Units |

| Injection Water for Oil Production | Onshore oil refinery |

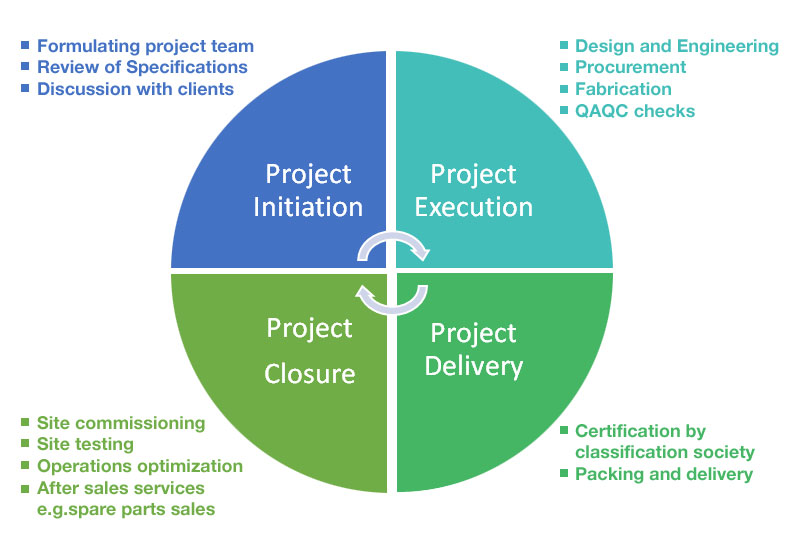

Hitachi Aqua-Tech is able to provide and manage the entire project cycle to our clients: